The Rapid Bridge Replacement Program shows the power of PPP and intentional contract development

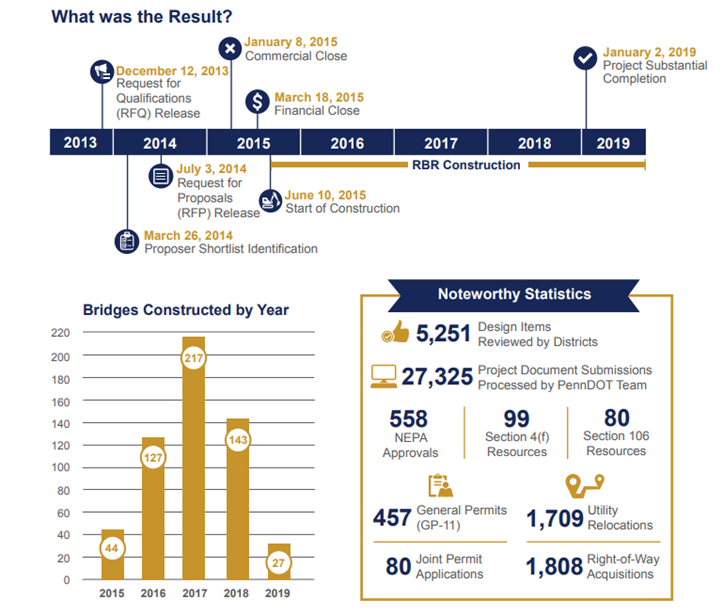

In 2013, Pennsylvania Department of Transportation (PennDOT) set out on one of the most ambitious Private Public Partnerships (PPP or P3) undertaken in the United States. The Pennsylvania Rapid Bridge Program (PRBP) aimed to replace 558 bridges across the state in a lighting-fast five years. Twelve years later it is still the largest multi-asset, multi-location initiative completed. The project was successfully completed in 2019 and is a great example of creative project delivery, innovative design and exceptional project management.

In 2021 and even as recently as this week in 2025, the American Society of Civil Engineers has given America’s bridges a rating of a C with glaring issues nationwide. As our infrastructure continues to age and carry ever-increasing traffic, creative solutions like the PRBP will be crucial for fast and effective project delivery.

When PennDOT set out on this project, Pennsylvania’s bridges ranked the worst in the country. Of the 25,000 state-owned bridges, over 4,100 (or 16 percent), were deemed structurally deficient in 2014. A Private Public Partnership was deemed the best solution to replace as many bridges and as cost effectively as possible. In this PPP, a development partner was selected to design, build, and maintain the bridges for a 25-year duration following completion.

Further benefiting PennDOT and taxpayers, the price of the project was spread out over the entirety of the 28-year construction and maintenance agreement, allowing PennDOT to allocate funds to other vital initiatives. Using both PPP and Design-build principles allowed for streamlined decision making, incentivized innovation and economy of scales otherwise unattainable in conventional construction delivery.

RBRP built 217 bridges in one year alone

The project success started in development of the scope of work. PennDOT deliberately grouped similar bridges based on region, size, and structure type to streamline designs and create economies of scale. By using design-build, where a single entity handles both design and construction, the project expedited site work, allowing construction to begin immediately after awarding the contract. Remarkably, PennDOT completed the program in under five years compared to 12 years under conventional methods. In 2017 alone, 217 bridges were completed, showcasing the program’s exceptional pace.

New technologies like polyester polymer concrete overlays, prefabricated concrete bridge spans and composite arch bridge systems were used to extend bridge longevity and accelerate construction. At an average cost of $1.6 million per bridge, including maintenance, PennDOT estimates the program saved 25 percent per bridge compared to traditional methods, making the PRBP a pioneering achievement in cost-effective and high-quality infrastructure delivery.

The PRBP has proven its impact. By 2023, structurally deficient bridges in Pennsylvania had decreased to 12.6 percent of the total share, as traffic and age continued to wear on all bridges. While challenges remain, PennDOT has shown the power of innovative project delivery methods, strong partnerships with the private sector, and well-scoped contracts. As the nation faces mounting infrastructure needs, solutions like the PRBP offer a blueprint for leveraging public and private resources to deliver world-class projects efficiently and cost-effectively.

Written by Aaron Shavel, Policy Fellow

The Alliance for Innovation and Infrastructure (Aii) is an independent, national research and educational organization working to advance innovation across industry and public policy. The only nationwide public policy think tank dedicated to infrastructure, Aii explores the intersection of economics, law, and public policy in the areas of climate, damage prevention, eminent domain, energy, infrastructure, innovation, technology, and transportation.