Background

Damage prevention is about avoiding harm to subsurface infrastructure and ensuring the safety of individuals and excavators. Well over 35 million miles of pipelines and other facilities run underneath homes and businesses, providing essential services to run all aspects of life from oil and natural gas pipelines, electrical power lines, water systems, telecommunications lines, cable television systems, and more.

In fact, there are more than three million miles of gas distribution lines alone in the United States. While any damage to an underground utility can create serious danger, this is especially true of gas distribution lines, because they are predominantly located in highly populated urban or sub-urban areas, and transport highly explosive natural gas.

According to the Pipeline and Hazardous Materials Safety Administration (PHMSA), there were 5,776 significant gas distribution line incidents over the past two decades (from 2004-2023). These incidents accounted for 254 fatalities, 1,048 injuries and nearly $13 billion in property damage.

While damage to other (non-gas) utilities may not be as risky to human life and safety, the economic consequences are equally serious, and excavation damage is the predominant culprit. The latest data reveals that in 2019 alone, excavation damage cost the U.S. over $30 billion. The same study suggested it may have been as high as $60 billion, and others estimate between $50 billion and $100 billion in true excavation damage costs – costs that accrue every year. Since that time, new all-time record high numbers of excavation damage incidents to buried facilities alongside high inflation means the true economic cost is far higher every year.

The primary problem with damage prevention is a simple lack of systemic adoption of best practices and use of available technologies and communication tools among stakeholders. As well as lack of law and regulation mandating the use of best certain available technology.

For example, despite significant improvements in GPS mapping technologies in recent years, incident rates have not declined. Increased use of the best available digital mapping technologies, improved communication between all parties (including utilities, excavators, locators), and stronger regulatory enforcement will go a long way in reducing the frequency and severity of incidents.

The Challenge

The underground utility network is, by nature, difficult to locate and track. Perhaps the greatest damage prevention challenge is ensuring that all parties communicate their collective knowledge of the location and properties of underground facilities with each other and more importantly, to the individuals performing the excavation work. Properly locating, identifying, and communicating the location of underground facilities should significantly reduce the risks of accidental damage.

Under the current system, excavators call in a ticket to a state-specific One-Call center to notify all utilities operating in the area when and where they plan to excavate. These utilities then mark the facilities themselves or send a locating firm (private contractors) to the work site to mark where their underground lines are buried. One method of this communication is to physically mark the ground with paint. When instituted, this method led to many improvements, but it is still subject to problems caused by inclement weather or other disturbances, including other excavation projects on or near the same utility, abandoned lines, or inaccurate maps.

In many cases, these markings are the only communication between the utility/locator and the excavators performing the work. One of the largest benefits of recent technological breakthroughs is the exponential improvement in our ability to share information with multiple parties immediately and simultaneously. This begs the question of why the damage prevention industry is not systemically using the best available technology to communicate the presence and location of underground infrastructure. This is a careful question to consider when facing accidents that can potentially cause death, serious injury, or billions of dollars in economic costs.

- Contractor fined in near-miss of Westby gas line; case prompts calls for new legislation [Wisconsin State Journal]

- OSHA fines LEAP and Techno Metal Post for ‘serious’ safety violations in connection with Farmington explosion [CM]

- Howland road reopens after gas line struck [WKBN 27]

- ‘I’m frightened’: City to shut down dangerous digging in Philly yard [WHYY]

- Texas Gas Service: line damaged by contractor [CBS 4 Valley Central]

- What a federal investigation into the Firestone, Colo., home explosion found [KUNC]

- Gas line damaged during excavation in Haverhill, Mass. [The Eagle Tribune]

- Residents evacuated and roads closed after contractor causes gas leak in Durham, N.C. [The News & Observer]

- Construction may play a part in rise of gas leaks in North Carolina [WCNC News]

- Three companies cited by labor department following deadly Durham, N.C., gas explosion inspection [ABC 11 News]

- Gas leaks caused by work crews in Charlotte, N.C., up 40% from last year, officials say [WSOC-TV]

- Gas leak leads to Orono, Maine, apartment complex evacuation [Sun Journal]

- Closed by the Durham, N.C., gas explosion, St. James Seafood aims to reopen early next year [The News & Observer]

- PG&E admits safety violations; agrees to pay $65M to settle California records claims [ABC 10]

- Columbia Gas ordered to stop work in Massachusetts [The Eagle-Tribune]

- Norfolk, Va., fire-rescue responds to two natural gas leaks at opposite sides of city [WTKR-TV]

- Construction crew hits gas line causing Eldersburg, Md., leak, road closure [Carroll County Times]

- Gas leak in Washington, D.C., prompts evacuations and Metro delays [The Hill]

- Onset, Mass., fire department responds to gas leak [CapeCod.com]

- Gas leak forced evacuations at Fairlawn Plaza in Topeka, Kan. [WIBW]

- Massive fire in Dekalb County, Ga., on Memorial Drive sparked by gas leak [CBS 46]

- Gas outage hits Salem, N.H., after work crews damage line [NBC Boston]

- Consumers Energy settles case alleging delayed response to MISS DIG calls [Michigan Radio]

- PG&E facing increased penalties for failing to locate, mark underground natural gas pipelines [Natural Gas Intelligence]

- Dozens in Southwest Baltimore and Catonsville, Md., lose water service after main breaks [The Baltimore Sun]

- Gas leak shuts down busy south Charlotte, N.C., road [WCNC]

- Gas site visits in Massachusetts lead to eye-opening observations [WWLP]

- Damaged gas line causes dozens of Lansing, Mich., residents to lose heat [FOX 47]

- WECT Investigates: Penalties for contractor who ruptured utility lines, snarled traffic in North Carolina [FOX Wilmington]

The Solution

The county’s public and private success is achieved daily through our reliable power and communication systems. Investing in leading-edge technologies will keep natural gas, electric, telecommunications and data transfer systems at the forefront of an increasingly advanced global network.

First, the best way to eliminate or reduce the number of incidents and bolster damage prevention efforts is to ensure that all parties have access to the best available information at an excavation site. The most ideal way to do this is to create and share digital maps of each dig site to identify the locations of all underground facilities. This information should be shared by all parties. Excavators on site should compare the digital map, photographs, and documentation with what they are seeing in real time at the worksite prior to beginning excavation.

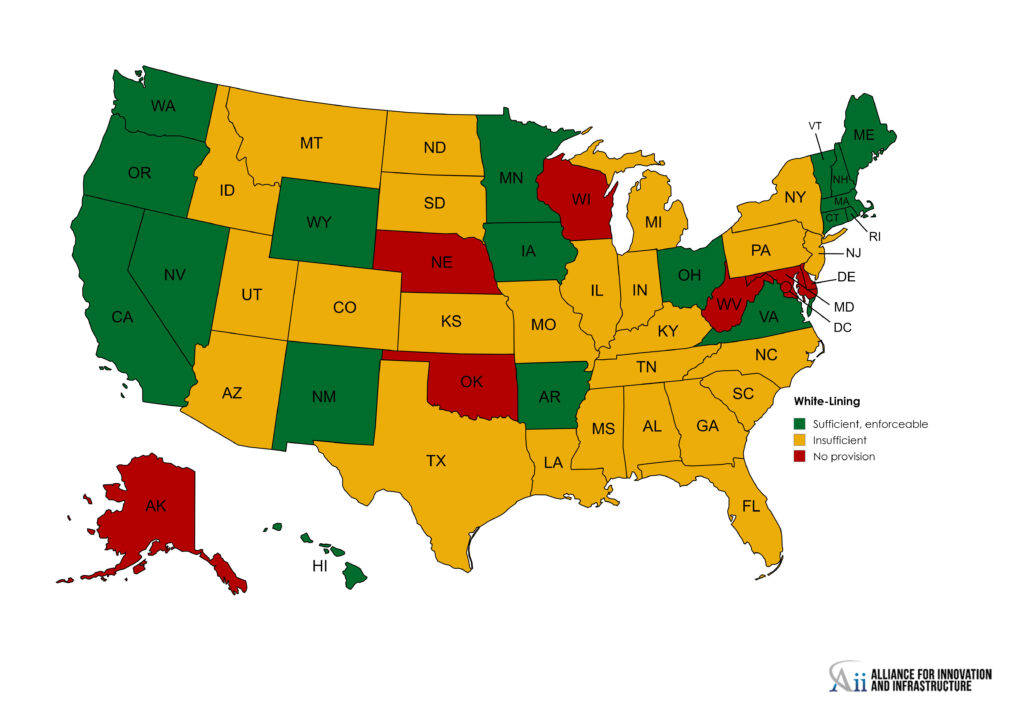

Further, states should ensure that the dig laws and best practices in place within their state are current and strictly enforced while making use of the best available safety tools. States should also review all standing exceptions to dial-before-you-dig laws and determine whether these exceptions create a safety risk, while encouraging digital notice and electronic white-lining to reduce the need for a phone call to the call center.

Finally, ensure the timely reauthorization and appropriate funding for the Pipeline and Hazardous Material Safety Administration (PHMSA), which regulates and oversees pipeline safety and certain underground utilities.

IS THIS THE BEST WE CAN DO? THE ANSWER IS CERTAINLY – NO

- Utilities need to take some responsibility for ensuring locating firms are using the best available technologies. They should also provide the most recent maps of their underground networks to the locators and the excavators.

- Locating firms need to do more than spray several lines of paint on the ground – they should provide digital maps of the dig site to all parties and clearly mark the utility lines on the images as well as the location and distance between any structures or other visible markers.

- Excavators need to notify One Call centers on any and all projects and should not assume that an exemption applies. They also need to be proactive in following up if a site description is confusing or the painted lines and flags create uncertainty about utilities in the dig area. Also, reviewing digital communications and comparing them to existing facility maps will help identify inconsistencies within the maps.

- States need to update regulations and ensure that best practices are reviewed periodically. They also need to review any standing exceptions to their respective “dial before you dig” laws and ensure these exceptions promote safety. Finally, states need to strictly enforce the regulations that are on the books and assess penalties accordingly.

- One Call centers need to be more proactive in upgrading their technologies to ensure that they are providing locators and excavators with the most accurate information possible. They should also provide all relevant parties with an unalterable electronic image of the site, rather than writing out a description in text.

THESE COMMUNICATIONS IMPROVEMENTS ALONE WOULD REAP LARGE BENEFITS.

- One Call centers and locating companies could provide excavators with far more accurate site descriptions and utility line markings.

- Excavators could compare the images and markings provided by the locators with utility maps, spot any potential inconsistencies, and contact the utility for clarification prior to arriving at the dig site.

- At the dig site, excavators could use the images to ensure that everything is where it is supposed to be, prior to breaking ground.

- Excavators could record where they install new facilities on digital maps, thereby improving the records and communications process going forward.

Featured Works Below

Policy Blog

Policy Briefs and White Papers

Cover Title Published Keywords Download hf:doc_categories hf:doc_tags

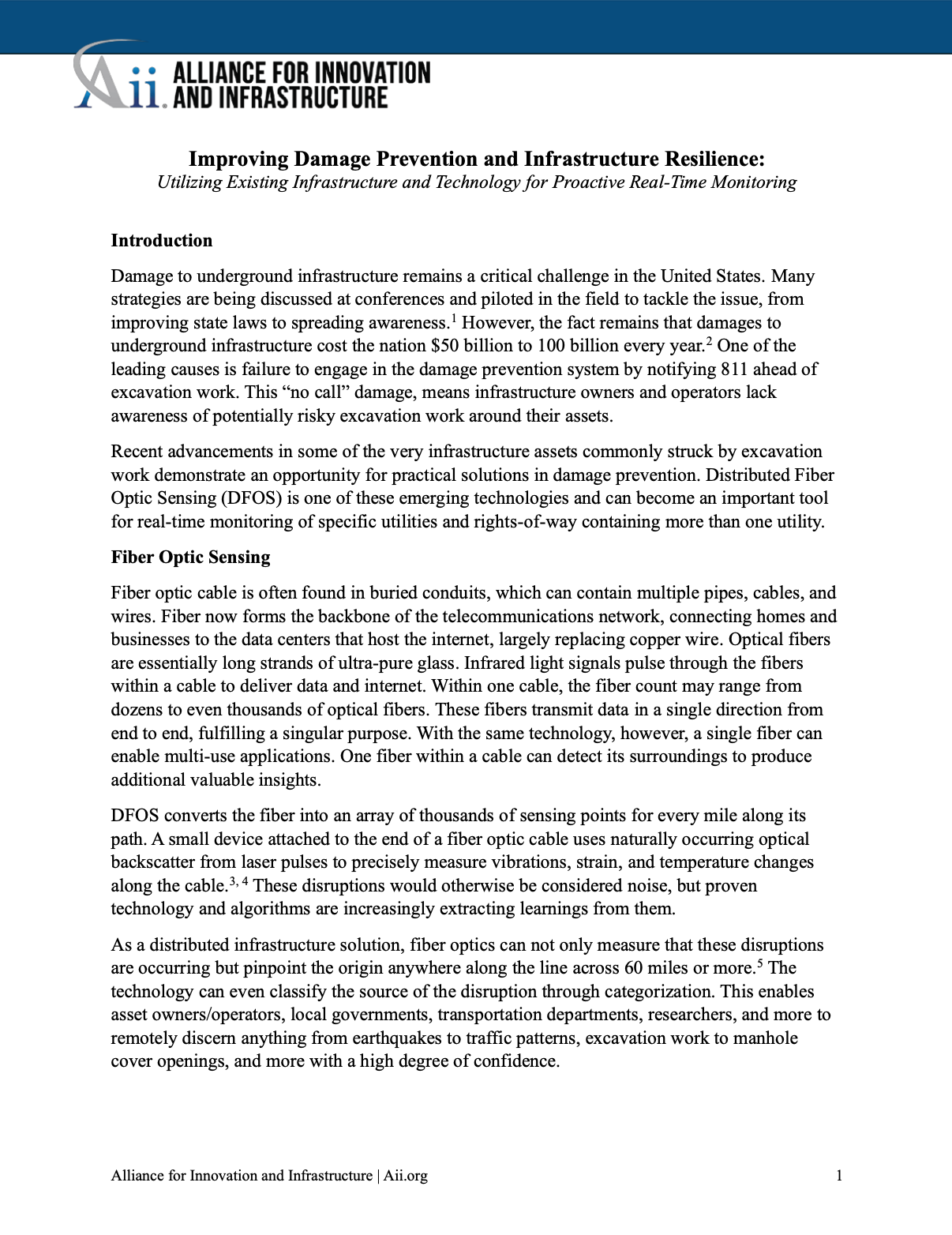

Improving Damage Prevention and Infrastructure Resilience: Utilizing Existing Infrastructure and Technology for Proactive Real-Time Monitoring March, 2025 Damage Prevention, Innovation and Technology policy-briefs damage-prevention innovation-and-technology

2024 Damage Prevention Report Card September, 2024 Damage Prevention, Innovation and Technology, Public Safety white-papers damage-prevention innovation-and-technology public-safety

Excavation Damage Reporting: The Basics of Data Collection and How States Require Strikes and Near Misses to Be Reported July, 2024 Damage Prevention white-papers damage-prevention

Damage Prevention One-Call Survey June, 2024 Damage Prevention, Public Safety policy-briefs damage-prevention public-safety

Improving Upon Our Dig Laws: Framing Out a Plan For Achieving a 50 Percent Reduction in Excavation Damage December, 2023 Damage Prevention, Energy, Public Safety white-papers damage-prevention energy public-safety

Unseen Threats to Texas Critical Infrastructure: The Risk to Buried Utilities and Targeted Policy Solutions to Protect Them October, 2023 Damage Prevention, Energy, Public Safety white-papers damage-prevention energy public-safety

Unseen Threats to U.S. Infrastructure Reliability April, 2023 Damage Prevention, Energy, Innovation and Technology, Grid policy-briefs damage-prevention energy innovation-and-technology grid

Unseen Threats to Public Safety April, 2023 Damage Prevention, Innovation and Technology policy-briefs damage-prevention innovation-and-technology

Unseen Threats to the U.S. Economy April, 2023 Damage Prevention, Energy, Economics policy-briefs damage-prevention energy economics

Unseen Threats to the Environment April, 2023 Damage Prevention, Energy, Climate and Conservation policy-briefs damage-prevention energy climate-and-conservation

Improving Upon Our Dig Laws: Why Data Must Take Center Stage to Reform Damage Prevention January, 2023 Damage Prevention, Innovation and Technology, Public Safety white-papers damage-prevention innovation-and-technology public-safety

Consensus Around Technologies: The Key Communications Technologies that Need to be Adopted to Improve Efficiency and Reduce Excavation Damages July, 2022 Damage Prevention, Innovation and Technology, Public Safety white-papers damage-prevention innovation-and-technology public-safety

Federal Damage Prevention Overview April, 2022 Damage Prevention, Energy, Public Safety policy-briefs damage-prevention energy public-safety

Excavation Damage to Underground Infrastructure: A Look at the Federal Damage Prevention Approach April, 2022 Damage Prevention, Energy, Public Safety white-papers damage-prevention energy public-safety

Improving Upon Our Dig Laws: Evaluating an Anomalous Year, Incorporating Technology, and Applying Lessons from the Past Decade December, 2021 Damage Prevention, Energy, Innovation and Technology, Public Safety white-papers damage-prevention energy innovation-and-technology public-safety

America’s Top Infrastructure Challenges June, 2021 Transportation, Damage Prevention, Innovation and Technology, Public Safety policy-briefs transportation damage-prevention innovation-and-technology public-safety

Building Back Better and Protecting What We’ve Built May, 2021 Damage Prevention, Energy, Innovation and Technology, Public Safety policy-briefs damage-prevention energy innovation-and-technology public-safety

Improving Upon Our Dig Laws: Proactive Steps to Combat Five Years of Rising Excavation Damage December, 2020 Damage Prevention, Innovation and Technology, Public Safety white-papers damage-prevention innovation-and-technology public-safety

2020 Damage Prevention Report Card October, 2020 Damage Prevention, Innovation and Technology, Public Safety white-papers damage-prevention innovation-and-technology public-safety

811: One-Call Before You Dig : The Development and Future of Damage Prevention Efforts August, 2020 Damage Prevention, Innovation and Technology, Public Safety white-papers damage-prevention innovation-and-technology public-safety

Improving Upon Our Dig Laws: Excavation Damage, Data, and Trends for Industry and Policymaker Analysis April, 2020 Damage Prevention, Innovation and Technology, Public Safety white-papers damage-prevention innovation-and-technology public-safety

Best Practices to Achieve Excavation Safety September, 2018 Damage Prevention, Energy policy-briefs damage-prevention energy

Improving Upon Our Dig Laws: How State Legislatures Can Help Us Dig Safer August, 2016 Damage Prevention, Innovation and Technology, Public Safety white-papers damage-prevention innovation-and-technology public-safety

Damage Prevention Report Card June, 2016 Damage Prevention, Innovation and Technology, Public Safety white-papers damage-prevention innovation-and-technology public-safety

Pipeline and Hazardous Materials Safety Administration Reauthorization March, 2016 Damage Prevention, Public Safety policy-briefs damage-prevention public-safety

Tracking Report

(Source: PHMSA)