Construction and excavation activity that damages buried infrastructure in the United States is on the rise. For over 10 years, damage numbers have risen – now exceeding 500,000 annual incidents of striking pipelines, cables, and wires below the surface. It is estimated that this leads to economic harm of over $30 billion every year, with other estimates soaring as high as $100 billion in yearly losses.

With the passage and implementation of the Infrastructure Investment and Jobs Act (along with other legislation and initiatives), upwards of a trillion dollars will be pumped into the economy in the next decade – much of it aimed at construction and infrastructure activities. There is a known and close correlation between construction spending and excavation damage, which is intuitive, because the more groundbreaking there is for new projects, the more power tools and shovels dig into the surface where buried facilities are concealed. It is also the case that as the economy and populations grow, more undergrounding takes place in which new pipes, cables, and wires are laid down to service new populations. This increases the over 20 million miles of underground infrastructure already in place and creates a higher probability of excavation damage for future projects.

For the latest available data, excavation damages likely hit a new all-time high in the United States. No doubt, this is one of the motivating factors prompting the Common Ground Alliance (CGA) to announce its new industry challenge: 50 in 5.

That goal seeks to cut damages in half over the next five years. While this is a needed, admirable, and ambitious goal, it likely will not succeed without substantial changes to the status quo. Across three areas of focus, CGA identifies:

- (1) Effective and consistent use of 811,

- (2) Key excavator practices (potholing, maintaining clearance, etc.), and

- (3) Accurate, timely utility locating.

These are, of course, needed areas of focus. As CGA points out, these three general areas are responsible for roughly three quarters of all excavation damage. But the initial solutions leave something to be desired. In short, the reforms needed extend well beyond simple adherence to best practice. Although these are necessary, they are not sufficient to cutting damages in half over five years. Instead, systemic changes will be needed to streamline the damage prevention process and improve safety.

We encourage CGA to produce a robust roadmap that the organization promotes publicly and holds its members to beyond issuing it as a challenge or goal. Included in their roadmap, we encourage consideration of the following areas that will be needed to halve damage numbers in five years:

Halving Excavation Damages Requires Systemic Reforms

While many of the steps outlined here are best practices, there will need to be a shift from simply acknowledging and pointing members to these practices and toward ensuring there are systemic changes that make them the norm. In some instances, that may be development of new platforms and user interfaces at One-Call centers, in others a shift of education by CGA and stakeholders, and possibly new regulatory standards.

The reforms must be systemic rather than individualistic or ad hoc, because a single stakeholder cannot effectively reduce damage trends; and in some cases, it is features of how the system works that enable the issues in the first place. Consider that in 2021, the features and function of the system itself led a group of stakeholders to form the Infrastructure Protection Coalition (IPC). This group came on scene to decry over $60 billion in annual waste and inefficiency in the way that states, one-call centers, utilities, and other stakeholders currently implement damage prevention practices. That $61 billion is distinct from – or in addition to – the enormous damage costs covered above.

Such inefficiency is no doubt a contributing factor behind stakeholder behavior within the system. While CGA’s 50 in 5 announcement included plans to unveil “a refreshed 811 tagline and animated logo this spring, which will join a new video series and other outreach tools that damage prevention advocates can use to implement behavior change campaigns around 811 usage,” this is unlikely to move the needle at all.

Needed reforms must include:

- • Broad shift to web-entry tickets

- • Improved ticket scheduling and prioritization options

- • Systemic use of electronic white-lining

- • Systemic use of enhanced positive response

CGA points out that 60 percent of damage is caused by professional contractors and excavators not notifying 811. When factoring in recent research by North Carolina 811 that indicates that when evaluating no-call damages, only 15 percent of respondents were unaware of 811, it seems that new logos and awareness campaigns are not the right tactic. Systemic reforms are. Implied by the NC811 findings, 85 percent of no call damage was likely an intentional no call.

At least anecdotally, but backed by numerous interviews and research, many excavators fully acknowledge the requirement to notify 811, but do not believe their ticket will be done quickly, efficiently, or accurately enough and take the risk of excavating anyway. Others choosing not to provide notice do so because markings are already on site from a previous job or another communication issue or systemic inefficiency in the past or recently caused them not to believe it was worth notifying on that particular job.

The findings of the nationwide IPC reports along with NC811 squarely indicate that to alter excavator behavior there need to be reforms to the system that will streamline it, build confidence, and promote efficiency.

That said, of course general education is critical and must continue. Aii has introduced its own Modern Roots March campaign to help build the average American’s and homeowners’ intuition about the need to call before they dig. This intentionally precedes National Safe Digging Month, which all must continue to improve outreach and education.

Web-Entry Tickets

Some of the reforms may be simply revising and improving the way awareness and education are done, such as directing excavators to click rather than call 811. By reducing the middle man, some excavators may be more confident and others may find that directly entering information themselves leads to more accurate site and proposed excavation descriptions (depending on who submits the requests).

In Canada, repeated analysis demonstrated that relative to notice made by calling, notice provided directly by clicking led to half the number of damages. (Said another way, when evaluating known damages for which notice was given, call-ins resulted in twice the damage number as web-entry.) This is attributable to clearer delineations and more precise notice. While this difference is between clicks and calls – a population entirely made up of excavators who did give notice – it is nevertheless a critical finding to explore and reform to implement. It is also possible that it could lower the barrier to notice that some professional contractors, homeowners, and the general public have, such as desire not to make a phone call to a call center.

Ticket scheduling and Prioritization

Combining this with a reform to allow ticket scheduling and prioritization is also essential to explore across the country as a systemic reform implemented at the one-call level. Scheduling and prioritization – which can be more easily communicated through web-entry – will go a long way in improving efficiency and reducing burdens on locators, which affect the timeliness and accuracy of locates. It can also reduce the potential for repeat locate requests if an excavator calls in tickets for a full mile project but will only complete work on the first quarter mile within the ticket window.

This is a small give and take between excavators and locators that one-calls can help facilitate to improve overall communication and collaboration among stakeholders. Allowing possible paid priority tickets may also be worth exploring for excavators on tight schedules.

Electronic White-Lining

Web-entry also provides the opportunity to incorporate one of CGA’s other recommendations (and improved best practice statement) pertaining to improved locate performance and accuracy. When entering information directly on a one-call website rather than calling an agent, the excavator can draw their own polygon to delineate the proposed excavation site. This is where electronic white-lining (EWL) can be utilized.

White-lining, or pre-marking, is the practice of preparing the excavation site with white paint, stakes, or flags so that locators can identify exactly where the excavation will take place and properly mark the entire site. This practice has long been promoted by the National Transportation Safety Board, the Pipeline and Hazardous Materials Safety Administration (PHMSA), and CGA, among others. Virtual or electronic white-lining allows this to happen virtually by digitally representing the dig site onto an overhead map.

A PHMSA-backed Virginia pilot study found “that the application of GPS technology in electronic white-lining can be of significant benefit to the one call process.” These include “improvements in safety” with “every stakeholder benefit[ing] at least indirectly.” Utilizing EWL “means less exposure time to locating crews, thus improving personnel safety,” while “smaller, more accurate areas” means “it is less likely that existing underground facilities will be affected; that is, fewer facilities will be affected within these smaller defined areas.”

The study also explains how the system suffers from poor notice when made in the traditional way or when excavators are not properly educated:

- Over-notification can affect from 40% to 60% of the total number of tickets issued for some types of utilities and has a very significant impact on stakeholder resources and the efficacy of the one-call process. Contributing to over-notification are vague and incorrect excavation site descriptions on locate requests submitted to the one-call center. Improving on the locational accuracy of locate requests and on the efficient communication of data was considered paramount to reducing over-notification.

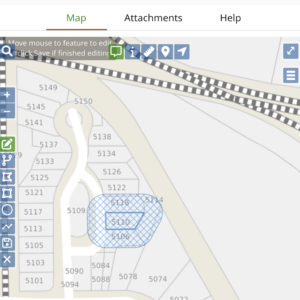

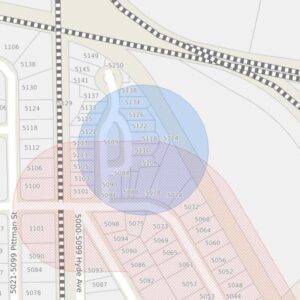

Consider the difference between a polygon entered directly by a homeowner landscaping a yard (left) with the notice given to six different locators (right) who each visited the site. While web-entry was given, the benefits of electronic white-lining were not present.

What was directly entered included a delineation of one lot, with a significant buffer zone generated in the shape of the lot. What locators received was an unnecessarily large buffer that touched 26 homes across two distinct neighborhoods, and they never saw the drawing made on the left. This above example is one that demonstrates the potential for electronic white-lining but also limitation that certain one-call centers need to reform. Currently, in some states even while web-entry is available and direct polygons can be created, the benefit is not passed onto locators, so the full benefit of the technology is not realized.

The PHMSA-VA study concludes: “The bottom line is that the application of GPS-enhanced electronic white-lining technology to the one-call damage prevention process has been demonstrated through this Pilot Project to benefit the damage prevention process.” This is likely why 61 percent of excavators surveyed by CGA emphasized the safety benefits of electronic white-lining, and why CGA concludes EWL is effective in “helping to reduce damages and lower costs.”

Because it can be done remotely, it also saves excavators time they do not need to spend visiting the site. This may also help improve systemic conditions for promoting use of the 811 system by the 85 percent of no-call excavators. It is clear that many of the effective solutions will also have positive feedback effects helping to alleviate root causes in other areas and with other stakeholders. This is also the case with our next recommendation.

Enhanced Positive Response

A final technology and best practice that needs nationwide implementation and systemic adoption is enhanced positive response (EPR). This is a technological best practice that facilitates the sharing of ticket data, virtual manifests, digital site photographs, facility maps, and other enhanced information commonly collected or generated by the locator to be passed along to the excavator. It not only closes the communication loop opened by the excavator when providing notice to the one-call center, but equips them with more information on the presence and location of buried facilities beyond spray paint markings that may be incomplete or disrupted before excavation begins.

In 2017, PHMSA completed a Report to Congress on Improving Damage Prevention Technology, in which the agency provided a number of recommendations. This safety agency’s top recommendation was “Develop collaboration/communication tools that foster better communication between the excavator and pipeline operator throughout the excavation process.” PHMSA then offered EPR as its example of its number one recommendation in the report’s “Expanding on the recommendations summary” section.

Enhanced positive response was demonstrated to reduce damage by up to 67 percent during a 2014 pilot program, with PHMSA validating the results through its 2017 report to Congress. In addition to the reduction of damage by 67 percent, findings included broad consensus of its value, including

- • “93% of Excavators and 88% of Facility Owners thought EPR made the job site safer”

- • “93% of Excavators and 72% of Facility Owners thought EPR improved damage prevention”

- • “92% of Excavators and 55% of Facility Owners thought EPR improved job efficiency”

Once again, excavators greatly benefit from and seem to demand this type of technology, practice, and systemic reform. It is likely that broader adoption of EPR along with EWL and similar technologies will help encourage behavior change in excavators while equipping them with the critical information they need to avoid damage. These technologies and practices are demonstrated to reduce damage, and will be essential to achieving a 50 percent reduction.

It will take all stakeholders to achieve a reduction in damage. In particular, CGA, one-calls, and regulatory agencies must work together and elevate standards so that the baseline first steps in the damage prevention process are to utilize electronic white-lining and enhanced positive response as steps one and two of every dig – as CGA has already vision cast.

The broad consensus around key technologies already recognized across industry and government must be put into action. Available data indicates that web-entered tickets reduce damage by half relative to call-in tickets, ticket scheduling and prioritization can reduce locator burdens, electronic white-lining has been shown to reduce damage, and enhanced positive response has demonstrated reduction in damage by 67 percent.

These four reforms – if adopted systemically – will begin a shift that will affect other behaviors and streamline inefficiencies. Without these components, there is no clear path to substantial reduction in damage, including the admirable 50 in 5 goal to see 50 percent reduction in only five years.

Written by Benjamin Dierker, Executive Director

The Alliance for Innovation and Infrastructure (Aii) is an independent, national research and educational organization. An innovative think tank, Aii explores the intersection of economics, law, and public policy in the areas of climate, damage prevention, energy, infrastructure, innovation, technology, and transportation.